CAR BATTERY DIN62MF

MODEL: DIN62MF

SIZE: 240*175*190*190mm (L*W*H*TH)

Characteristics:

1.Sealed Maintenance-free.

2.Special lead plate design, Anti-acid, Anti-shake.

3.Excellent cold resistance, excellent cold cranking capacity.

4.Exclusive polypropylene case design to protect batteries from vibration and impact.

5.Heat sealed design to maximize strength and rigidity to prevent electrolyte leakage.

6.Long-lifespan, high stability.

7.Application: Car

TIGER HEAD, 555, TIHAD

Each procedure is followed by quality checking machine. Quality control department inspect batteries before making shipment also.

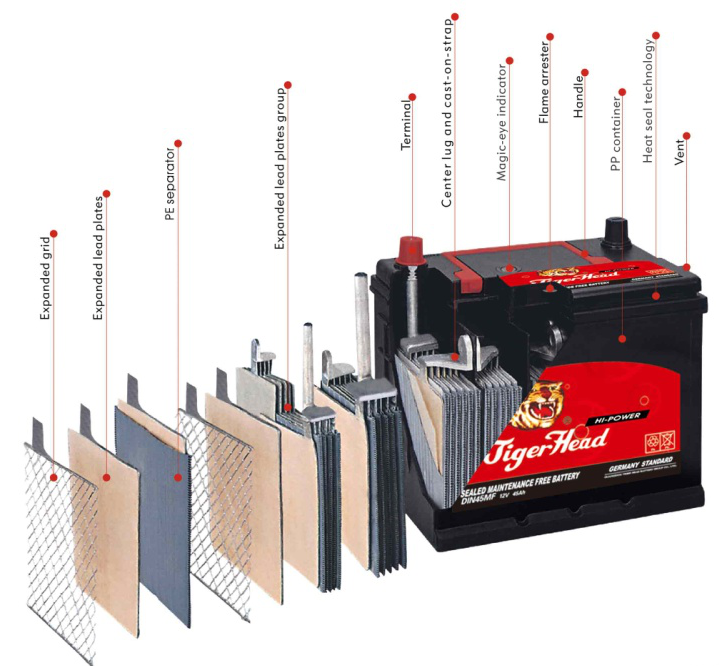

CAR BATTERY STRUCTURE

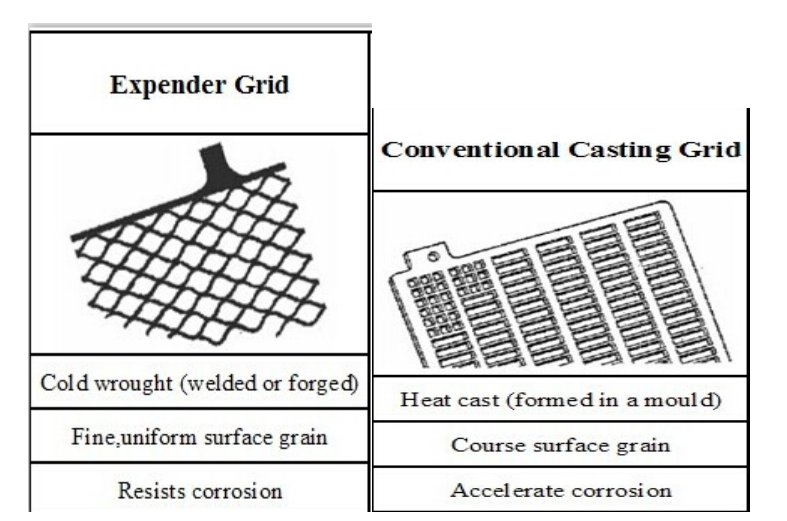

Special Lead Plate Design

Take combination of Expender Grid and Casting Grid, make battery more powerful, more durable.

Standard of Lead Acid Car Battery

CAR BATTERY PRODUCING PROCESS

1.Casting process

2.Expanding and board coating process

3.Solidification process

4.Assembling process

5.Enveloper stacker procedure

6.Cast on stripe procedure

7.High-pressure pole reversal testing procedure

8.Hole melting procedure

9.Internal resistance testing procedure

10.Big cover heat sealing procedure

11.Pole burning procedure

12.Gas Leak testing procedure

13.1. Acid filling procedure

14.2. Charging procedure

15.3. Acid dumping procedure

16.4. Acid filling procedure

17.5. Acid adjusting balance procedure

18.6. Small cover heat sealing procedure

19.7. Gas Leak testing procedure

20.8. Washing and drying procedure

21.9. High-current discharging testing procedure

22.10. Pole brushing procedure

23.11. Serial Numbering procedure

When the rechargeable car battery factory produces products, there is usually a special quality inspection machine, and the battery will be checked before the transfer.